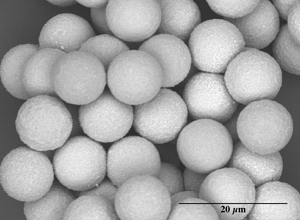

ICA用 Spherica™ 粒子

・次世代フィラー

・シルバーフレークより銀が少ない

・低抵抗で低コスト

・ジェット印刷とDispensingが可能な球形

Available on-shelf products are:

30µm Ag: Spherica™ Ag-30-01

10µm Ag: Spherica™ Ag-10-01

4µm Ag: Spherica™ Ag-4-01

追加のサイズは、さまざまなアプリケーションに合わせてカスタマイズできます。

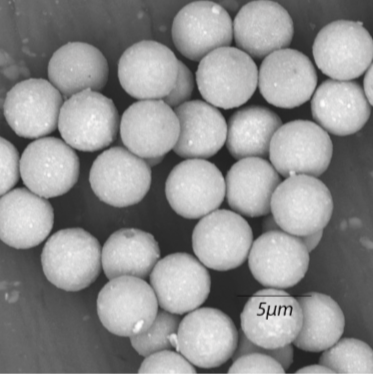

Sperica Ag-4-01

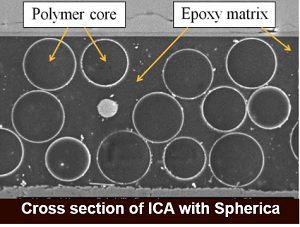

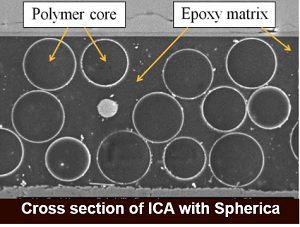

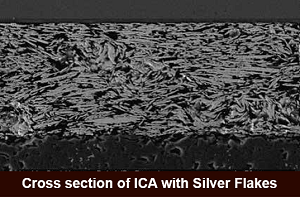

Sperica Ag-4-01 is the next generation filler for isotropic conductive adhesives (ICA). The silver-coated polymer particles contain less than silver flake filler,providing low resistivity while cutting costs. Spherica Ag-4-01's polymer core is thermally matched to adhesive resins,which can improve joint reliability compared to silver flake filler. Furthermore,the spherical shape enables jet-printing and dispensing without nozzle.

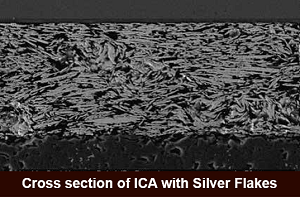

SPHERICA Ag-4-01 VS SILVER FLAKES

PARTICLE PROPERTIES

Particle diameter : 4 ± 0.5μm Polymer core material : Acrylic Typical CV : <3% Metal,nominal thickness : 125-160nm Ag Metal content : 67.5 wt% Theoretical density : 2.9g/cc Electrical resistivity (at 60wt%) : 0.2-0.4mΩ x cm Recommended wt% particles*: 67-73%

FEATURES

.Next generation ICA filler .Lower cost than Ag flake fillers .Superior reliability .Sutable for jet-printing and dispensing .Reduced sedimentation

PARTICLE PROPERTIES (CONT'D) Chemical compatibility Compatible with isopropanol,toluene(less than 15min), most epoxy resin system and acylics. Applicable temperature range: Tested for bonding temperatures up to 180℃ Application Notes Spherica Ag-4-01 filler behaves differently than traditional silver flake filler when mixed into an adhesive resin. The spherical shape of Spferica Ag-4-1 will charge the rheological properties of the adhesive compared silver flakes, therefore modification of adhesive may be required. Additionally,the optimum loading of Spherica Ag-4-1 should be determined for each adhesive resin system, and depends on the viscosity of the adhesive and application requirements. A loading in the range 67-73wt% is recommended to achieve good performance.

Spherica Ag-10-1

Spherica Ag-10--1 is the next generation filler for isotropic conductive adhesives(ICA). The silver-coated polymer particles less than silver flake filler,providing low resistivity while cutting costs. Spherica AG-10-01's polymer core is thermally compared to silver flake filler. Furthermore, the spherical shape enables jet-printing and dispensing without nozzle closing issues.

SPHERICA Ag-10-01 VS SILVER FLAKES

PARTICLE PROPERTIES

Particle diameter : 10 ± 1 μm Polymer core material : Styrene DVB Typical CV : <5% Metal,nominal thickness : 126-154nm Ag Metal content : 46.0 wt% Theoretical density : 1.8g/cc Electrical resistivity (at 60wt%) : 0.5-1mΩ x cm Recommended wt% particles*: 45-65%

FEATURES

.Next generation ICA filler .Lower cost than Ag flake fillers .Superior reliability .Sutable for jet-printing and dispensing .Reduced sedimentation

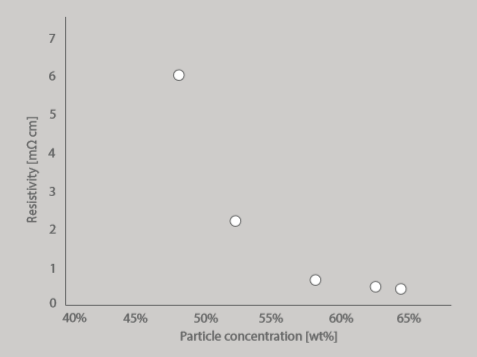

PARTICLE PROPERTIES (CONT'D) Chemical compatibility Compatible with isopropanol,toluene(less than 15min), most epoxy resin system and acylics. Applicable temperature range: Tested for bonding temperatures up to 180℃ Glass transition temperature of polymer is approx.100℃ Application Notes Spherica Ag-10-01 filler behaves differently than traditional silver flake filler when mixed into an adhesive resin. The spherical shape of Spferica Ag-10-1 will charge the rheological properties of the adhesive compared silver flakes, therefore modification of adhesive may be required. Additionally,the optimum loading of Spherica Ag-10-1 should be determined for each adhesive resin system, and depends on the viscosity of the adhesive and application requirements. A loading in the range 45-65wt% is recommended to achieve good performance.

percolation curve for Spherica Ag-10-01

in Conpart’s test adhesive which uses a low/medium viscosity resin.